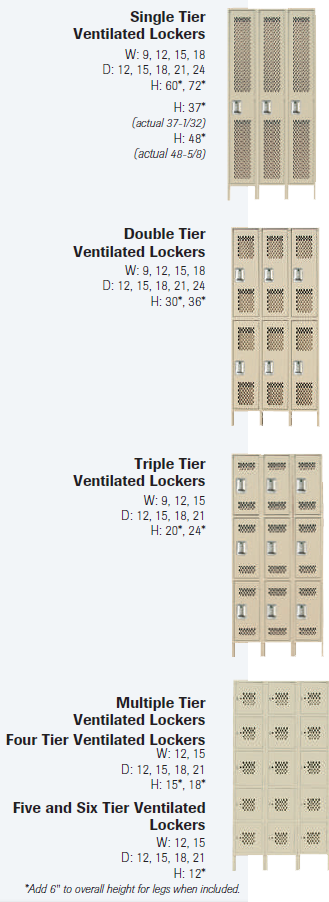

HEAVY-DUTY VENTILATED LOCKERS

CONFIGURATIONS

SPECIFICATION SUMMARY

• 14-gauge door with 16-gauge frame

• 16-gauge body parts with

18- gauge backs

• Full loop type hinges

• Secure multi-point locking system

• Stainless steel recessed handles

• One piece 14-gauge door

• Powder coat finish

• Doors and sides punched with diamond shaped perforations

• Built in padlock loop

• Built in locks are also available

(see page 25)

• Fully assembled construction optional

MATERIAL

Prime, high grade Class 1 mild annealed, cold-rolled steel free from surface imperfections. A.S.T.M.-A1008. Galvannealed steel available for high humidity atmospheres. A.S.T.M.-A653. Bolts to be zinc plated or subjected to other rust-retardant treatment.

Quiet-Plus

Eliminating metal to metal contact, all Lyon locker doors are fitted with nylon lockbar guides to reduce clanging and provide smoother, quieter operation.

In addition to quieter lock bars, Lyon Quiet-Plus locker doors include a sound deadening door panel. The resulting combination minimizes noise levels caused by opening and closing locker doors.

FEATURES

• Lockbars feature nano roller latching fingers that engage 12-gauge door jambs for maximum security

• High security single point latches are designed for built-in locks with wrap around technology. Includes padlock hasp

• The door frames are formed by overlapping and welding the junction between the horizontal and vertical members to form a rigid unitized structure that fully frames the door

• Standard hinges are full loop design and provide more strength than larger butt type hinges

• Full loop hinges are inserted through slots in the door and frame to maintain alignment and increase strength

• Door frames include integral full height 16-gauge door strikes to reinforce door edges

• One piece doors formed from 14-gauge prime, high grade class 1 steel

• Three latch points on single tier doors and two on double and triple tier doors

• One piece recessed handle pockets add strength to the handle area and eliminate the vulnerable seams of formed handles

• Soft rubber bumpers, at door jamb locations, cushion door slams

• Doors and sides include diamond perforated ventilation

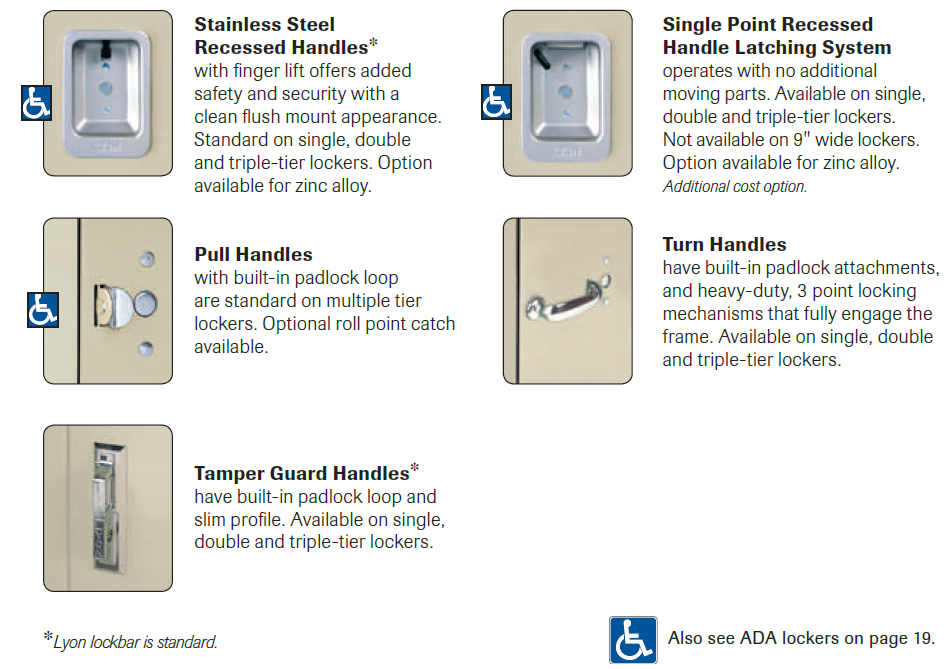

Handle Options

18-gauge backs.

Door Frame – 16-gauge formed steel channels. Vertical members shall have an additional flange to form continuous door strike. Corners shall be lapped and welded into a rigid assembly. In addition, bottom cross members shall have tang at each end that fits through slot in rear flange of upright frame member to prevent twisting out of alignment. Top and bottom cross members shall provide support for front edge of locker top and locker bottom.

Door – One-piece, 14-gauge steel on single, double and triple tier with both vertical edges formed into channel-shaped formation; top and bottom shall be flanged at 90 degree angle. On multiple tier lockers, hinge side shall be formed into channel shaped formation with other three sides flanged at 90 degree angle.

Ventilation – Sides and doors shall be punched with diamond shaped perforations. Optional solid sides available.

Door Jambs – 48” and higher single tier lockers shall have three door jambs; double tier and triple tier lockers shall have two jambs welded to side of door frames to engage locking device. Design and gauge of jamb shall prevent freeing of locking device by prying. Each jamb shall have easily replaceable soft rubber bumper.

Hinges – Shall be not less than 2” high, .050” steel, 5 knuckle, full loop design forming double thickness on each leaf. Hinges to be set in slot in door and frame and projection welded to frame and securely attached to door. Hinge pin to be spun over at ends to resist removal. Single-tier lockers 48”, 60” and 72” high to have three hinges. All other tiers to have two hinges – all on right hand side of door. Optional continuous hinge available.

Quiet Locking Device – Single tier locking device shall engage frame at three points; double tier and triple tier at two points. Channel shaped locking device with full length reinforcing ribs shall be a quiet design utilizing nylon guide inserts to reduce metal to metal contact. The locking device shall include

a latch finger that engages the 12-gauge door jamb. Lock bar shall be enclosed on three sides and operate within the channel formation of the door. Locking device shall be prelocking so mechanism can be locked in open position – door locking automatically when closed. An optional single point latch shall be available except on 9” wide lockers. Box locker shall have one-point locking device with a 14-gauge lock clip for attaching padlock. Doors also to be provided with lock hole filler to permit use of built in lock.

Handles – On single, double and triple tier lockers, handles shall be stainless steel recessed. No moving parts are to operate against outside surface of locker. Padlock attachment to be integral part of lift which shall be attached directly to locking bar and protected by fixed handle housing. Handle to provide built in padlock strike. The recessed handle shall be 4-1⁄8″w x 6-1⁄16″h x 1-1⁄4″d. Multiple tier lockers shall be equipped with a 16-gauge door pull with padlock attachment when not used with built in locks.

Shelves – Single tier lockers shall have one 16-gauge shelf approximately 9” below top. Flanged on all four sides for strength with the front flange turned 45 degrees for safety and attached at no less than two points through each side flange. Only single tier lockers 48″ and taller have shelves.

Coat Hooks – Single tier, double tier and triple tier lockers shall have one double prong hook and three single prong wall hooks. 5⁄8” diameter coat rods are standard in 18” and 21” deep knocked down single tier lockers, replacing ceiling hook. All hooks to be zinc-plated or subjected to a comparable rust retardant treatment and attached with two nuts and bolts.

Number Plates – Optional aluminum number plates with etched figures at least 3⁄8” high. All lockers shall have the number plate punching located at the near top of the doors.

Standard Finish – Exposed steel parts shall be thoroughly cleaned, given a bonding and rust inhibitive phosphate treatment and then electrostatically sprayed with powder coat.

NOTE: Contact Lyon for finish compatibility with any chemicals.

Anchoring – To prevent tipping or injury, Lyon strongly recommends that lockers be floor and/or wall anchored. “Z” Type Bases are available for lockers without legs.

Recess Trim – End and top recess trim for lockers to be placed in wall recesses shall be 18-gauge formed steel with a 2-3⁄4” wide face and shall be bolted to locker frames.

Top recess trim to be in approximately 5’0” lengths with a formed splice cap to cover joints and to hold top recess trim in alignment. End recess trim to be 2-3⁄4”higher than lockers and will lap over ends of top recess trim for a hairline joint at top of corners.