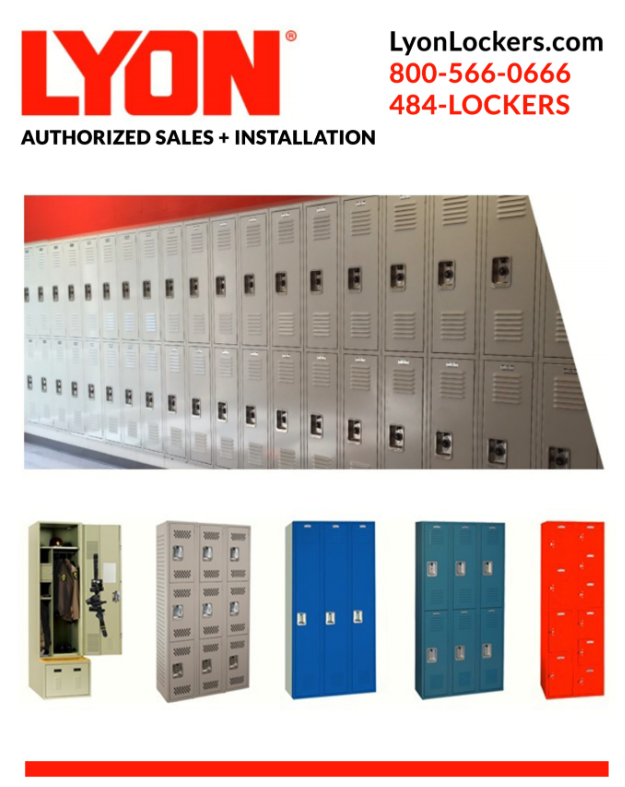

DELUXE COLLEGIATE & COLLEGIATE LOCKERS

CONFIGURATIONS

SPECIFICATION SUMMARY

All-Welded

• All seams and Joints welded for rigidity

• Optional compartments shipped knocked down

• 16-gauge body parts with 18-gauge backs

• Full loop type hinges

• Powder coat finish

• 14-gauge sheet metal or no door compartments

• 16-gauge frame

• 16-gauge sheet metal

• All metal locking systems

• Optional installation of compartments at factory

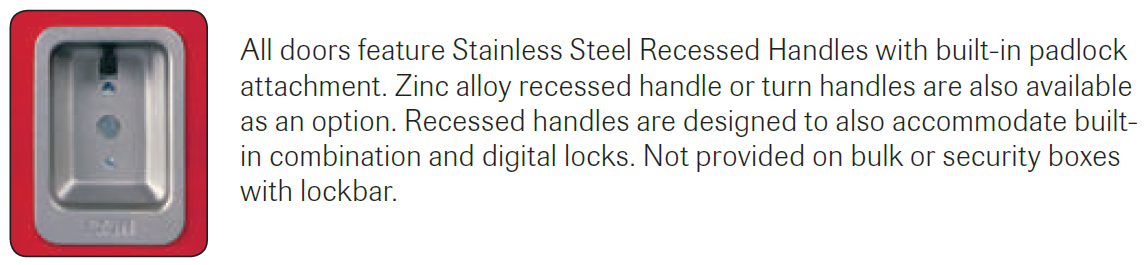

• Stainless steel recessed handle Knocked Down

• 14-gauge sheet metal or

16- gauge sheet metal or no door

• 16-gauge frame

• 16-gauge sheet metal sides

• All metal locking systems

• Stainless steel recessed handle

• Powder coat finish

*Specify All-Welded or Knock Down at time of order

MATERIAL

Prime, high grade Class 1 mild annealed, cold-rolled steel free from surface imperfections.

A.S.T.M.-A1008. Galvannealed steel available for high humidity atmospheres. A.S.T.M.-A653. Bolts to be zinc plated or subjected to other rust-retardant treatment.

FEATURES

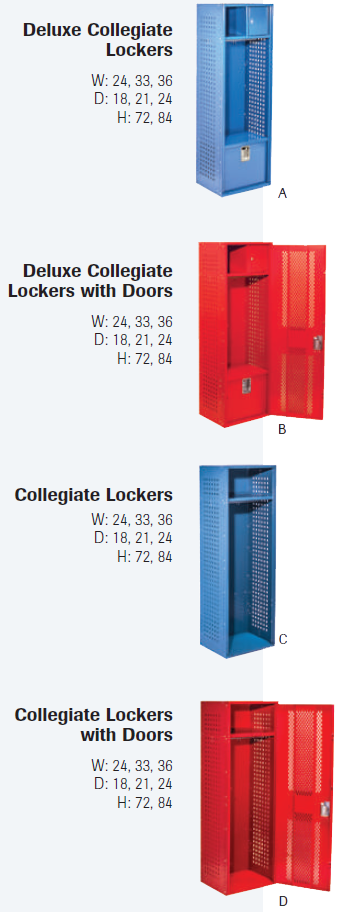

A- Deluxe Collegiate Lockers offer additional security for special equipment or assigned gear. 18″ high interior compartment bench with padlock hasp. Upper compartment door may also be equipped with built-in key or combination lock.

B- Deluxe Collegiate Lockers with Doors offer the same design and construction features as above, plus the added security of a reinforced door.

C- Collegiate Lockers are designed to provide easy access to equipment and uniforms in team locker rooms. Shelf included.

D- Collegiate Lockers with Doors are recommended for storing bulky uniforms of hockey and football teams, offering up to 36″ wide compartments.

Includes solid back and diamond perf sides. Optional diamond perforated door. Is also available as solid or louvered door.

Handle Options

NOTE: Lyon strongly recommends that exposed side end sheets be of solid material.

Door Frame – Shall be 16-gauge formed steel channels. Vertical members shall have an additional flange to form continuous door strike. Corners shall be lapped and welded into a rigid assembly. Bottom cross members shall have tang at each end that fits through slot in rear flange of upright frame member to prevent twisting out of alignment. Top and bottom cross members shall provide support for front edge of locker top and locker bottom.

Optional Door – Optional door is supplied only upon request. One-piece, 14-gauge steel with double both vertical edges formed into channel-shaped formation; top and bottom shall be flanged at 90 degree angle.

Quiet Locking Device – Locking device shall engage frame at three points. Channel shaped locking device with full length reinforcing ribs shall be a quiet design utilizing nylon guide inserts to reduce metal to metal contact. The locking device shall include a latch finger that engages the 12-gauge door jamb. Lock bar shall be enclosed on three sides and operate within the channel formation of the door. Locking device shall be prelocking so mechanism can be locked in open position – door locking automatically when closed. An optional single point latch shall be available security. Doors also to be provided with lock hole filler to permit use of built in lock.

Hinges – Shall be not less that 2″ high, .050″ steel, 5 knuckle, full-loop forming double thickness on each leaf. Hinges to be set in slots in frame and projection-welded to frame – securely attached to door. Hinge pin to be spun over at ends. Single tier lockers 72″ and 60″ high to have three hinges, 48″ high to have two hinges, and multiple-tier to have two hinges – all on right-hand side of door.

Hat Shelves – Lockers shall have one 16-gauge hat shelf approximately 12″ below top. Flanged on sides and back-channel formation on front flange – attached at no less than two points through each side flange.

Coat Hooks – Lockers shall have one 5/8″ diameter coat rod and four single prong wall hooks. All hooks to be zinc-plated or subjected to a comparable rust-retardant treatment and attached with two nuts and bolts or rivets.

Number Plates – Optional aluminum number plates with etched figures at least 3⁄8″ high. Can be attached to door or security box

Finish – Steel parts shall be thoroughly cleaned, given a bonding and rust inhibitive phosphate treatment, and a powder coat finish. Complete locker must be finished in same color.

NOTE: Contact Lyon for finish compatibility with any chemicals.

Anchoring – To prevent tipping or injury, Lyon strongly recommends that lockers be floor and/or wall anchored.

Optional Bulk Lock-Up – Optional bulk lock-up is designed to allow for bulk storage and lockup capability. Bulk compartment lid acts as a seating area as well. Bulk lock-up is 18″ in height, full depth of locker, and consists of the following components:

• Bin front assembly made of 14-gauge steel.

• Lid assembly made of 12-gauge steel and connected to 14-gauge continuous hinge with 0.410″ knuckle diameter. Attachment angle is 12-gauge. Hasp located on front of lid is 14-gauge. Hasp allows for locking capability with use of padlocks.

• Lid support angles made of 12-gauge steel and support the lid in the closed position.

Optional Security Box – Designed to allow for small compartmental storage with lockup capabilities.

Security box ships knock down, is 12″ in height, 12″ in width, and spans the depth of the locker opening. The security box consists of the following components:

• Right hand side and hinge member–made of 16-gauge steel with formations that make up the right side of the box and is punched for the weldment of continuous hinge.

• Left hand side and lock member–made of 16-gauge steel with formations that make up the left side of the box and is punched for the weldment of single locking padlock hasp.

• 16-gauge right hand hinged door formed with flanges on all four sides. Door is equipped with punching to allow for built-in locks.

• Top frame member made of 16-gauge steel. Top frame member acts as a frame closure for upper portion of box between the door and the exterior locker top.

• Security box sits on the standard Collegiate locker shelf. Shelf is punched with holes to attach the security box through the two side members. Collegiate shelf acts as a bottom for the security box. Box is located on the right side of the locker unit.